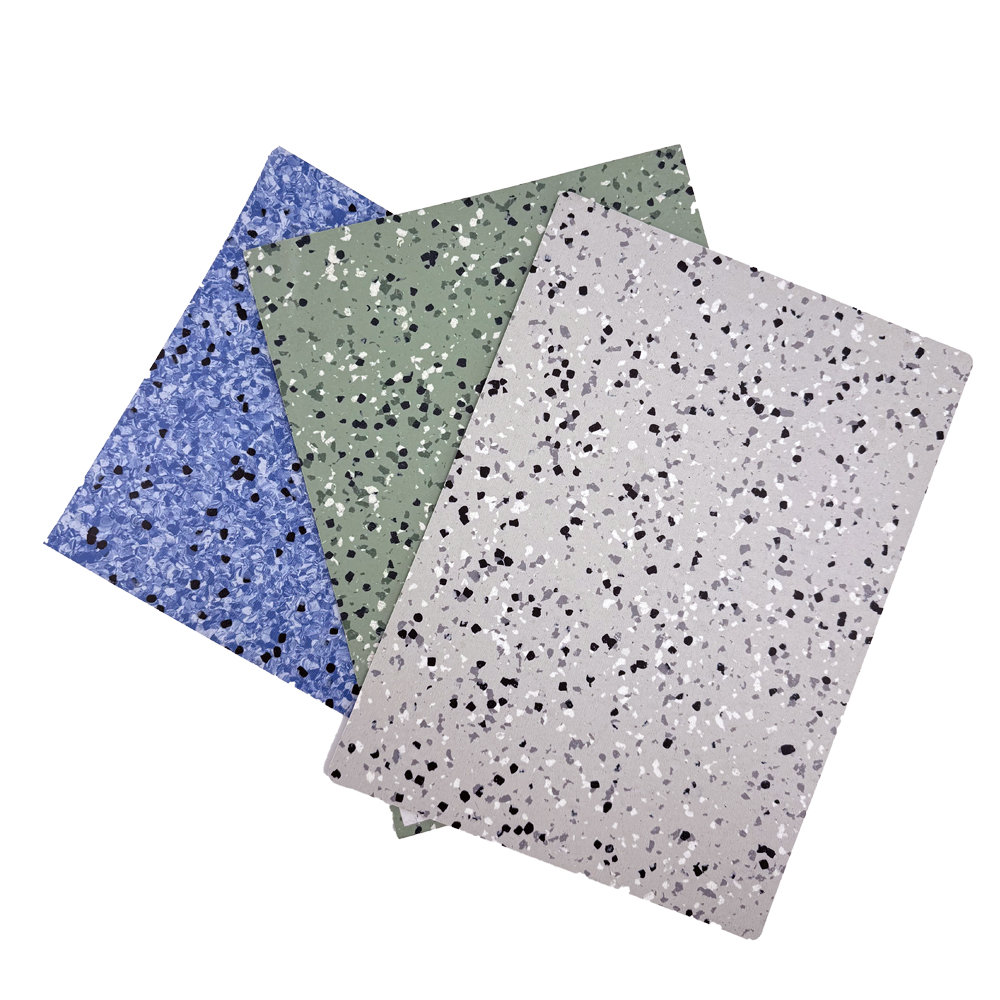

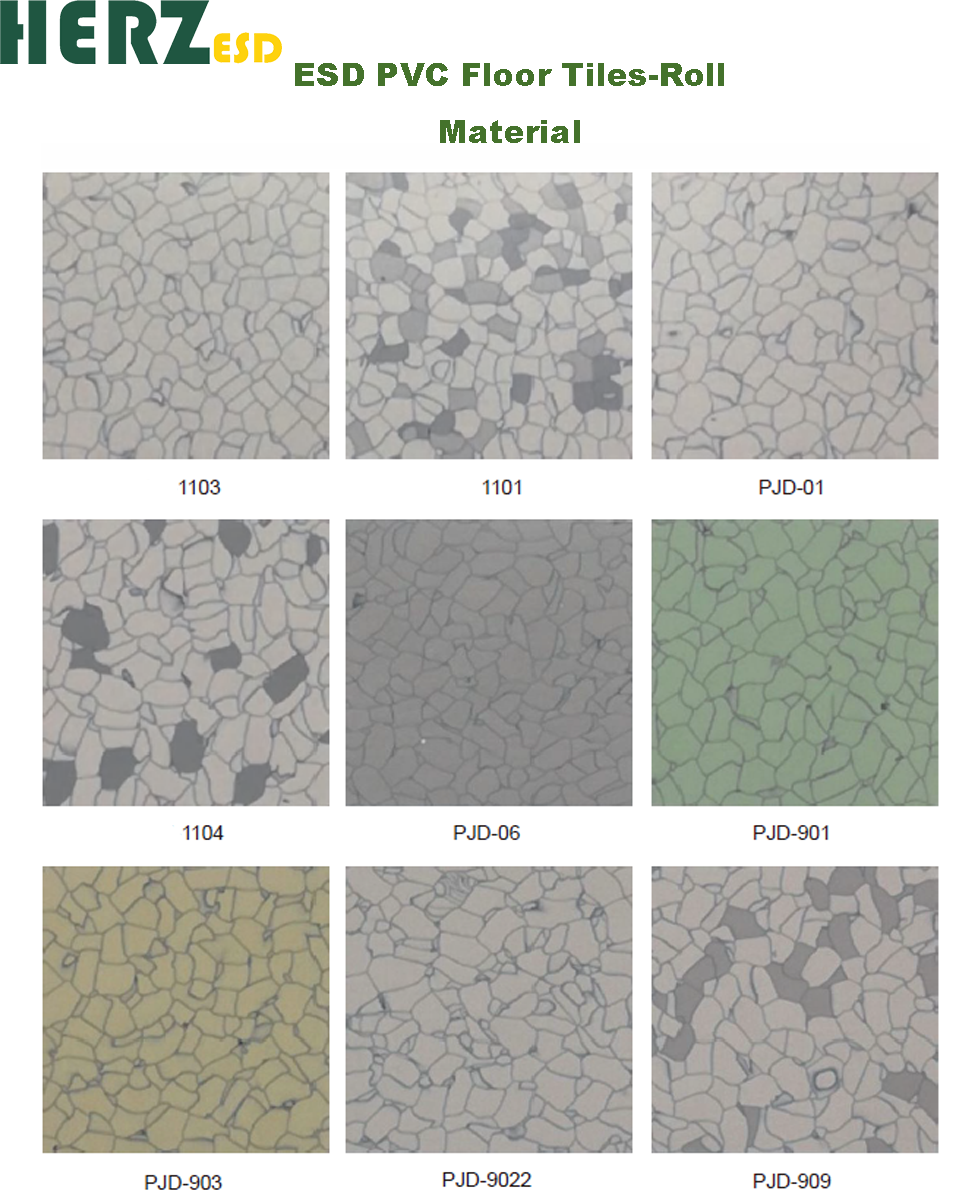

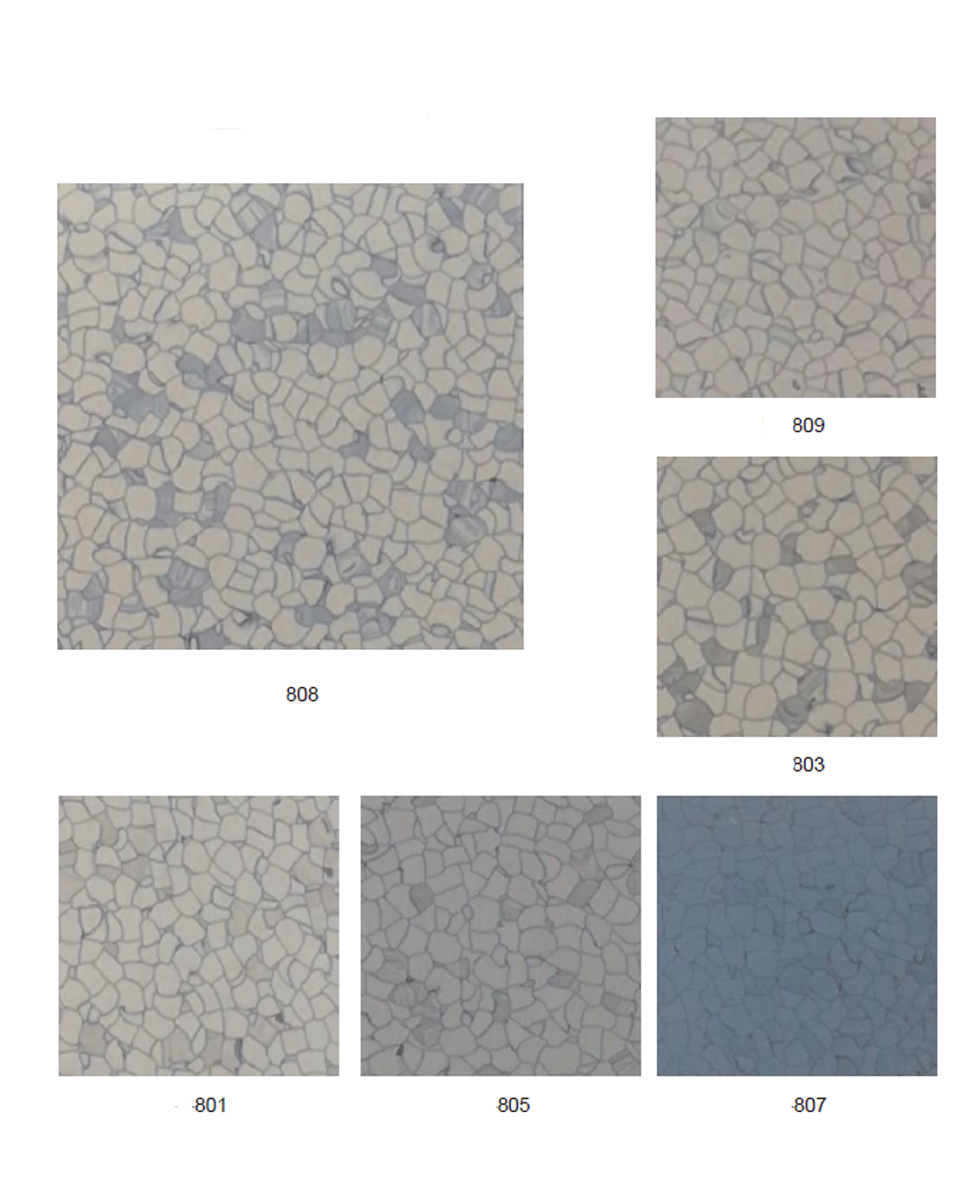

Conductive PVC Flooring Mat ESD Vinyl Flooring Anti-static PVC Floor ESD Tiles Sheet

item No :

ESD vinyl flooring is widely used in clean rooms, manufacturing & assembly workshops of electronic products, hospitals, data centers & computer rooms, and other areas that require an anti-static environment.

Products Description

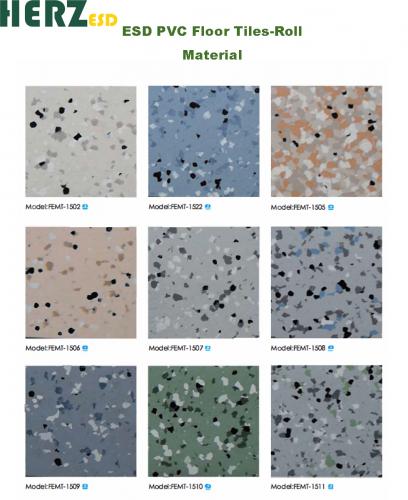

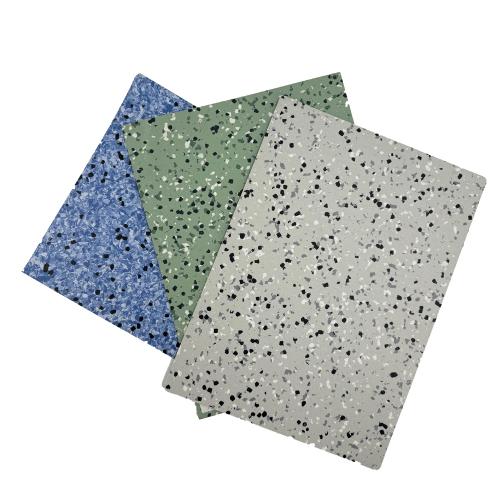

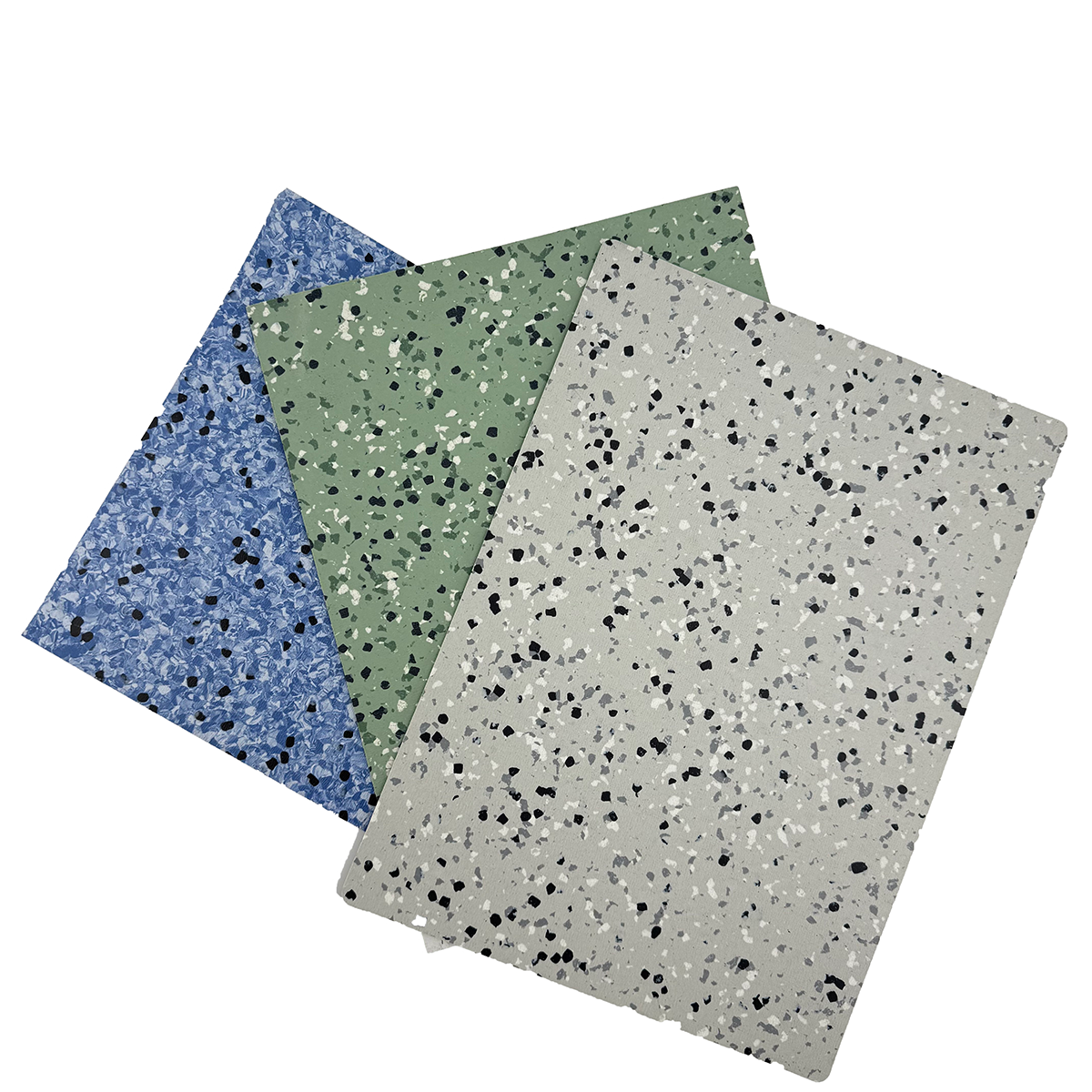

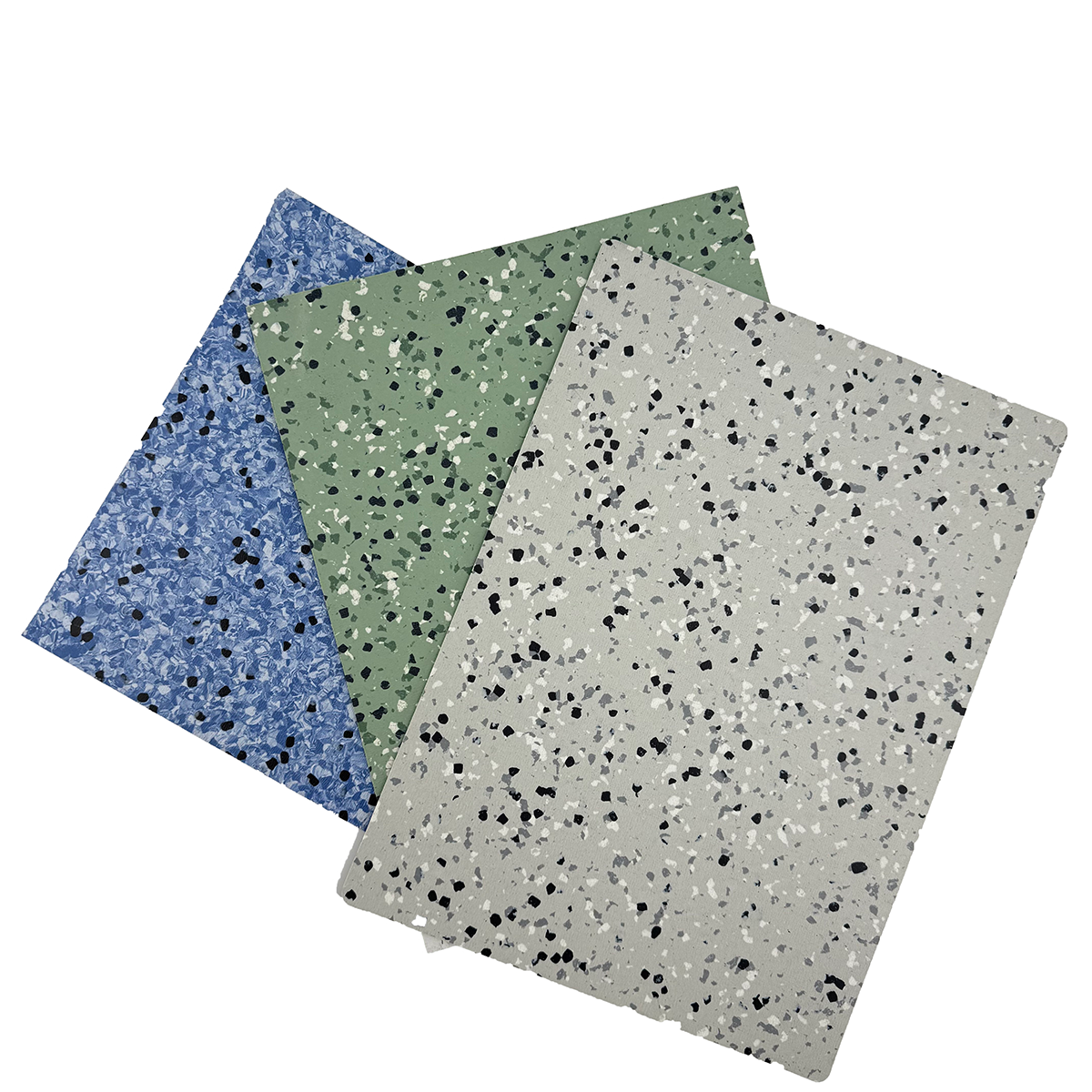

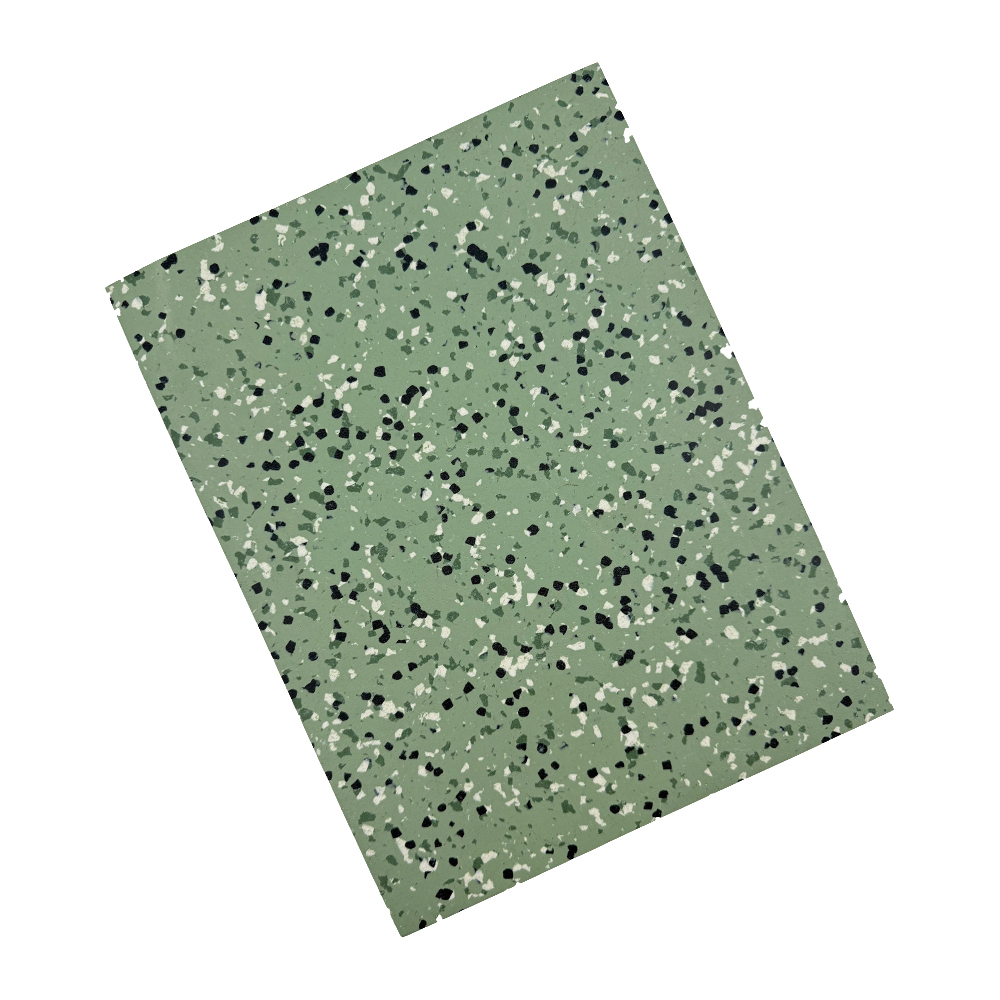

There are two kinds of ESD vinyl flooring, ESD tile and ESD sheet. Both tile and sheet are homogeneous structures, and electronic resistance can meet both conductive(10^4-10^6Ω) and static-dissipative(10^6-10^9Ω).

The ESD sheet inserts carbon-encapsulated granules throughout the whole thickness, and a conductive backing is attached, providing optimum and consistent conductive properties.

| Product name | ESD Vinyl Flooring Sheets/ ESD Vinyl Flooring Tiles |

| Material | PVC |

| Thickness | 2mm/2.5mm/3mm |

| Size | 600x600x2.0mm/2.5mm/3.0mm Or 2.0m x 20m x 2.0mm, Customized |

| Application | Industry/ Office/ Home/Cleanroom |

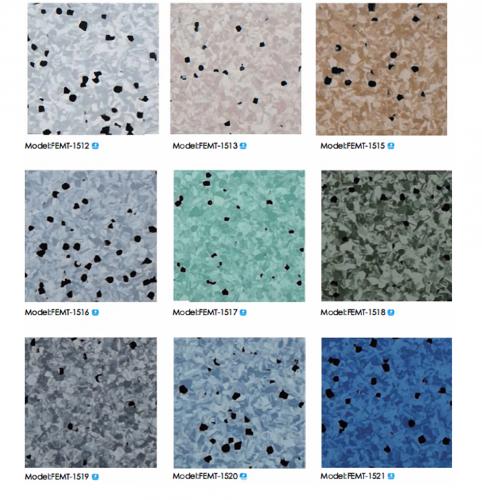

| Color | Multi Color |

| Feature | Conductive, ESD |

| Thickness | 2mm/2.5mm/3mm |

| Surface | 1.0x10E04-1.0x10E06 ohm/1.0x10E06-1.0x10E09 ohm |

| Package | Roll/ Pieces |

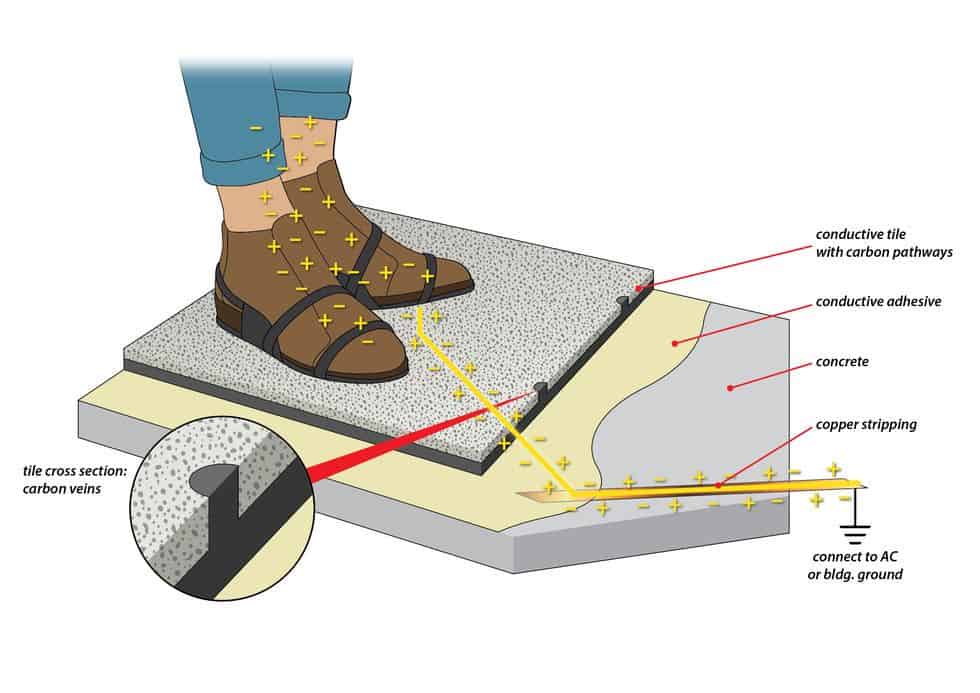

How Does a Static-Control Floor Provide a Path to Ground?

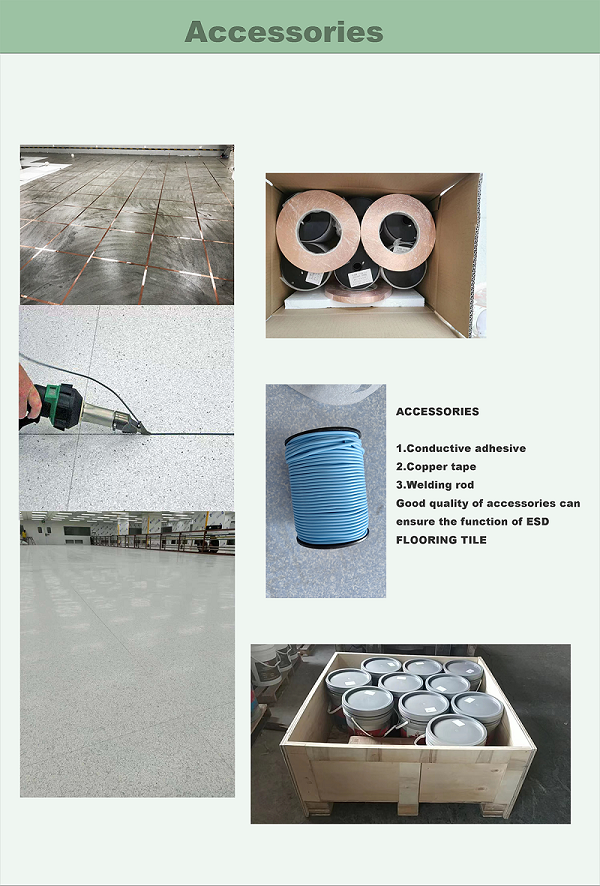

In the manufacturing process, ESD floor tiles are loaded with conductive elements, such as carbon, graphite or particles coated with metals, that provide electrical conductivity. When the floor becomes electrically charged, these conductive elements act as an electrical chain, conducting electricity from the surface of the floor through its entire thickness. Static-control flooring is installed over an electrically conductive underlayment, such as conductive copper foils or carbon-loaded adhesive. The underlayment forms a conductive ground plane that unifies all the contiguously-installed tiles in the room.

Copper grounding strips, attached to the underlayment, are connected to either an electrical outlet or an earth ground such as a steel I-beam or a grounding rod. This electrical connection allows static to complete its circuit and flow safely to ground.

The static generated when people walk on the ESD floor flows at a controlled rate through the conductive elements in the floor, across the underlayment, to the copper strips, to ground. Instead of remaining on the floor’s surface or moving through humans to whatever they touch, static is drawn downward, toward ground, where it can no longer wreak havoc.