Home > ESD Workplace > ESD PVC Floor > Conductive Flooring Homogeneous ESD PVC Floor Tiles PUR Coated Antistatic Vinyl Flooring esd

Conductive Flooring Homogeneous ESD PVC Floor Tiles PUR Coated Antistatic Vinyl Flooring esd

- item No :

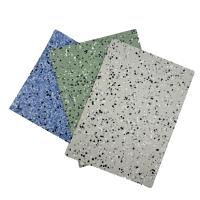

- ESD vinyl flooring is widely used in clean rooms, manufacturing & assembly workshops of electronic products, hospitals, data centers & computer rooms, and other areas that require an anti-static environment. There are two kinds of ESD vinyl flooring, ESD tile and ESD sheet. Both tile and sheet are homogeneous structures, and electronic resistance can meet both conductive(10^4-10^6Ω) and static-dissipative(10^6-10^9Ω).

- Inquiry now

Detailed description

Product Description

ESD vinyl flooring is widely used in clean rooms, manufacturing & assembly workshops of electronic products, hospitals, data centers & computer rooms, and other areas that require an anti-static environment. There are two kinds of ESD vinyl flooring, ESD tile and ESD sheet. Both tile and sheet are homogeneous structures, and electronic resistance can meet both conductive(10^4-10^6Ω) and static-dissipative(10^6-10^9Ω).

How Does a Static-Control Floor Provide a Path to Ground?

In the manufacturing process, ESD floor tiles are loaded with conductive elements, such as carbon, graphite or particles coated with metals, that provide electrical conductivity. When the floor becomes electrically charged, these conductive elements act as an electrical chain, conducting electricity from the surface of the floor through its entire thickness. Static-control flooring is installed over an electrically conductive underlayment, such as conductive copper foils or carbon-loaded adhesive.

The underlayment forms a conductive ground plane that unifies all the contiguously-installed tiles in the room. Copper grounding strips, attached to the underlayment, are connected to either an electrical outlet or an earth ground such as a steel I-beam or a grounding rod. This electrical connection allows static to complete its circuit and flow safely to ground. The static generated when people walk on the ESD floor flows at a controlled rate through the conductive elements in the floor, across the underlayment, to the copper strips, to ground. Instead of remaining on the floor’s surface or moving through humans to whatever they touch, static is drawn downward, toward ground, where it can no longer wreak havoc.

Packaging & Shipping

FAQ

1. WHY IS ESD – ELECTROSTATIC DISCHARGE – A PROBLEM?

2. WHY IS STATIC-CONTROL FLOORING NEEDED?

When we walk on certain floors, the friction between the soles of our shoes and the floor generates a static charge.* This static charge stays in place, on the surface of our body, until we touch something, then it jumps or discharges to that person or object.

This release of electricity is called an electrostatic discharge, or ESD. When static discharges to a static-sensitive electronic component, the sudden rush of electrical current can damage or destroy its internal circuitry.

In most workplace environments, the static generated when people walk is the biggest contributor to random ESD events (or problems caused by electrostatic discharge). For this reason, a static-protective floor—or an ESD floor/footwear combination—is the cornerstone of any effective static-control program.

When we walk on certain floors, the friction between the soles of our shoes and the floor generates a static charge.* This static charge stays in place, on the surface of our body, until we touch something, then it jumps or discharges to that person or object.

This release of electricity is called an electrostatic discharge, or ESD. When static discharges to a static-sensitive electronic component, the sudden rush of electrical current can damage or destroy its internal circuitry.

In most workplace environments, the static generated when people walk is the biggest contributor to random ESD events (or problems caused by electrostatic discharge). For this reason, a static-protective floor—or an ESD floor/footwear combination—is the cornerstone of any effective static-control program.

Related products

- About us

- Categories

- ESD Packing Material

- ESD Storage & Circulation

- ESD Workplace

- ESD Personal Protection

- Cleanroom Products

- News

- Contact us

info@herzesd.com

info@herzesd.com +8613122355237

+8613122355237 8613122355237

8613122355237

copyrignt 2017-2025 沪ICP备19000699号-3

Powered by semcms PHP 2.1